Customized electric motor silicon steel stamping

Product Description

The most common way to reduce iron consumption is to adopt high quality Silicon Steel Sheet with high permeability and low loss. In addition, the thickness of silicon steel sheet is one of the important factors that affect the iron consumption of the motor. The main domestic silicon steel sheets are 0.5mm thick, while many foreign products begin to use 0.35mm or even 0.27mm thick silicon steel sheet. As the thickness of silicon steel sheet decreases, the magnetic properties also increase

The Principal Activities of Yuanzhong

Custom metal stamping and stator and rotor lamination to serve the global market.

High efficiency motor core

1.Product Description

| Product Name | stator and rotor stack |

| Material | B50A4700 (Or Designated material) |

| Application | High efficiency motor |

| Component | stator and rotor lamination |

| Service | OEM |

| Packing | Wooden box(Can be customized) |

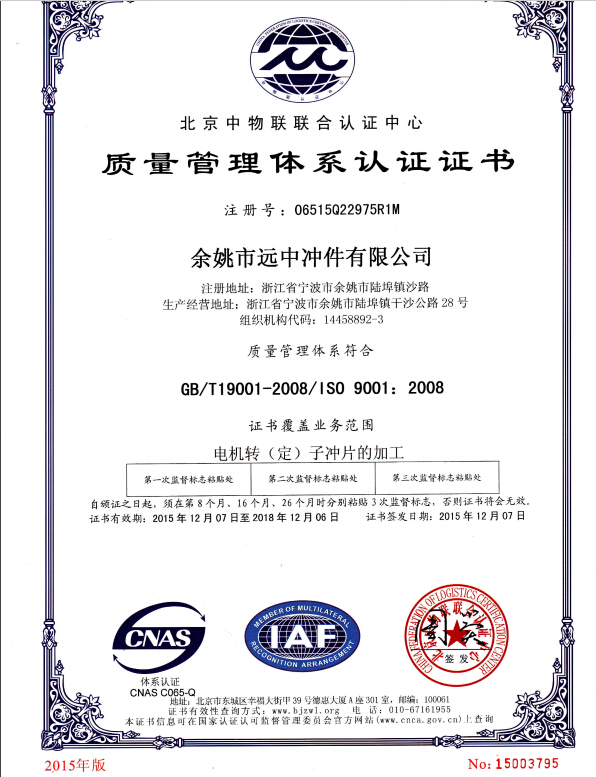

| Standard | IS09001; 2008 |

2. Produce show

3.Product Size

| Type | Materials | Main Function |

| High efficiency motor core | B50A4700 | High efficiency motor |

4. Company profile

YUYAO YUANZHONG SALT PIECES CO.LTD, The factory is specializing in producing kinds of motor iron core and motor punching plate.

The existing equipment including Japan AIDA200T,AIDA125T and Taiwan INGYU80T, in all

8 high speed precise punches, also with the equipment of Slitting Ling, precision surface grinder and so on. In addition, the company is also equipped with more than 40 ordinary lathes with the capacity from 5 to 10 tons. We normally produce motor iron core about 80 thousand per months.

The company in 2001 has passed the IS09001; 2000 standard quality system certification. And take this as an opportunity to carry out the implementation carefully, complete control of product quality to satisfy customers.

5. Production process

6.Our Certifications

7.Quality Control

(1)Accurate to 0.01mm, the deviation is not exceeding 0.02mm

(2)Manual Inspection and Measuring Profile Projectors

(3)ISO 9001:2008 certificate

8.Packing

Packing Details : customize appropriate wooden case according to product size and weight

Desiccant + Water Proof Cloth + PP + Solid Carton

9. Contact us

Product Categories : High Efficiency Motor Core